Titanium Control © Wind River

- Wind River launches its Titanium Control solution for Industrial IoT

- An on-premise cloud-scale infrastructure based on open standards

- Virtualises traditional physical subsystems enabling control systems

- Offers edge-to-cloud connectivity

Announcements around industrial Internet security and control are coming thick and fast this week. Yesterday we reported on an innovative concept from the Fraunhofer Institute that links to legacy industrial fieldbus architectures and features in-built data cryptography. Today it’s the turn of Wind River, which has introduced its new software platform that enables critical infrastructure companies to evolve aging legacy control systems not previously designed to support IoT.

Traditional industrial control systems were obviously not designed to support IoT, therefore most are of a rigid, single purpose design and have a relatively high cost to deploy, integrate and maintain. Also, Wind River says that the obsolescence cycle is driving system updates that require new systems to keep pace with innovation while maintaining or lowering capital costs.

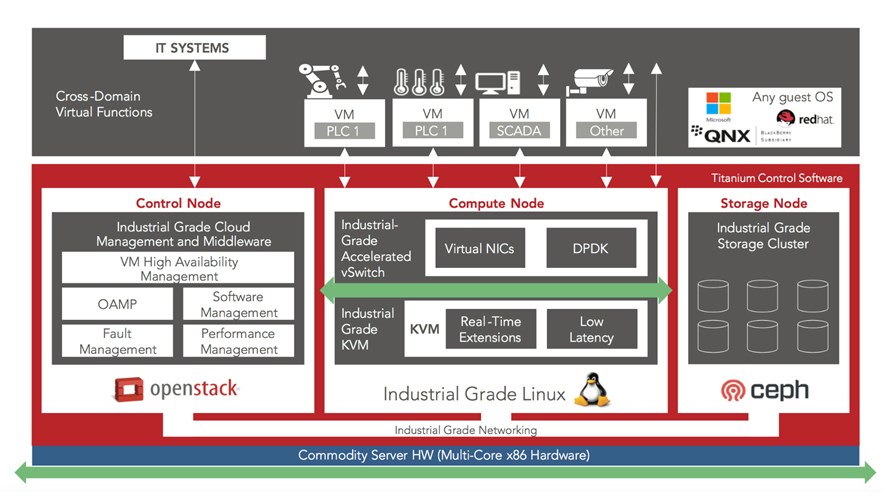

Its new Titanium Control is a commercially deployable on-premise cloud infrastructure that virtualises traditional physical subsystems using a platform based on open standards. Wind River says it can deliver the high performance, high availability, flexibility and low latency needed to reduce capital and operating expenses, as well as minimize unscheduled downtime for industrial applications and control services at any scale. It also provides high reliability for applications and services deployed at the network edge, for example in fog deployments.

“The influx of new IIoT technologies now entering the automation market has the potential to be a major disruption to existing business models that have been relatively stable for decades,” said Harry Forbes, research director at technology research firm ARC Advisory Group. He says the combination of real-time operating systems and on-premise cloud computing technology enables the virtualisation of real-time automation applications that until recently could only be implemented in embedded systems hardware. “The implications of this capability for the manufacturing automation market are very far-reaching, and automation suppliers are noticing.”

Titanium Control features de facto standard open source software for on-premise cloud and virtualisation, including Linux, real-time Kernel-based Virtual Machine (KVM) and OpenStack. The solution is scalability from two to over 100 compute nodes and supports software updates and patching with no service interruptions.

“With the emergence of Industrial IoT, companies are looking to deploy next-generation open and secure control systems,” said Jim Douglas, president of Wind River. “With the addition of Titanium Control to our product portfolio, Wind River is driving a new industrial era through virtualisation, real-time performance and edge-to-cloud connectivity.”

Email Newsletters

Sign up to receive TelecomTV's top news and videos, plus exclusive subscriber-only content direct to your inbox.